Glass layer is finished, now for some nasty sanding.

Some sanding and then fiberglass can start.

The hull is still lined up well so sanding has started with a bit of attention on keeping the C/L loft values. Some hulls do not seem to be too strict on that point.

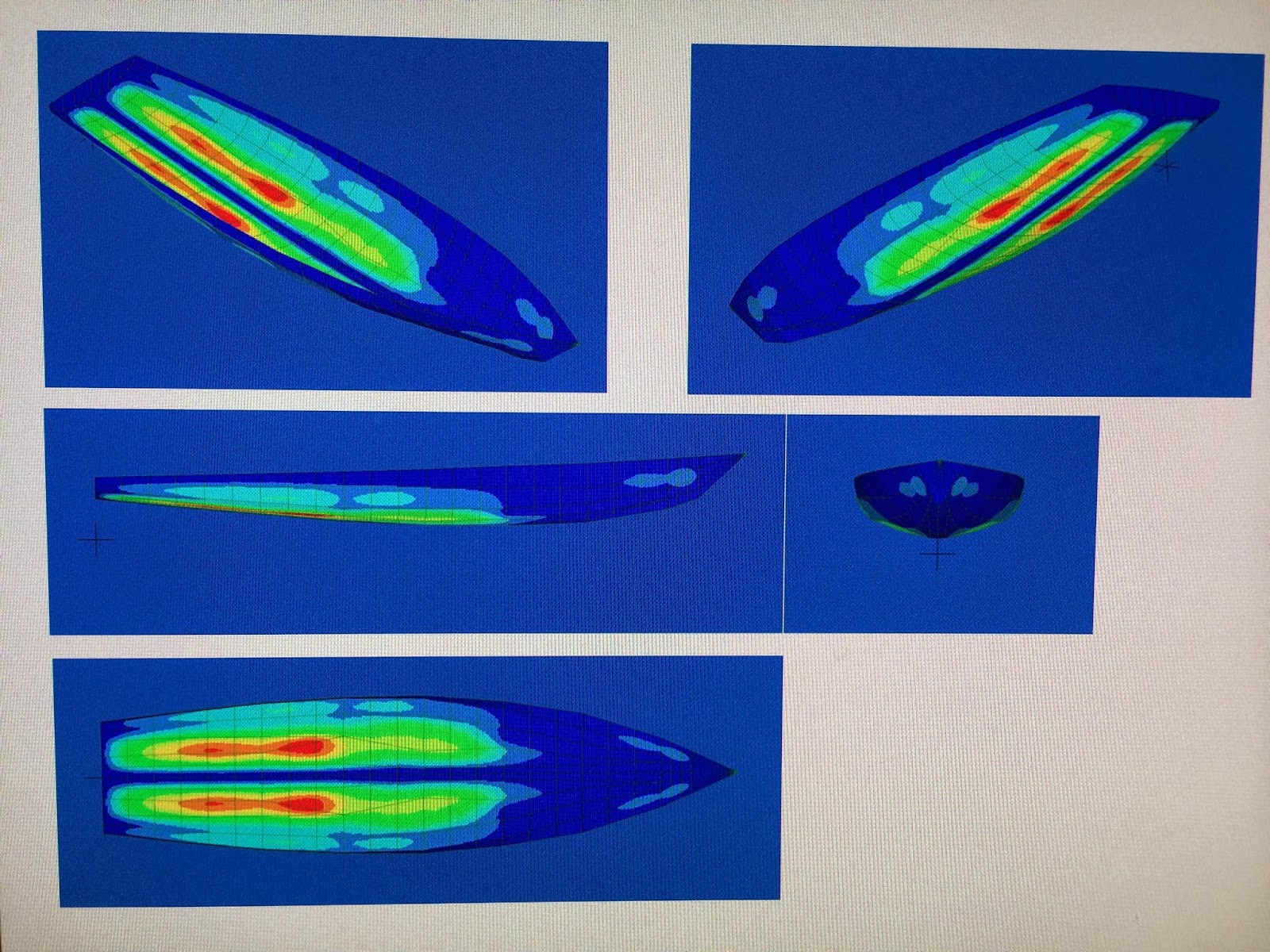

Finish cold molding --- complete 4-7-15Install 5 mm offset Douglas fir strip to front leading edge of hull.Rough sand and check loft values.Final staple check and rough epoxy fill of surface damage.Scrape hull, sand hull all over.Apply epoxy + Q cell and fare hull all over.Sand faring layer.Apply 10 oz e-glass layer all over. 4-21-15- Cleanup and sand if needed.

- Cleanup and sand if needed.

- Apply epoxy + Q cell and fare hull all over.

- 1st orbital sand faring layer.

- Apply epoxy + Q cell and fare hull all over.

- 2nd orbital sand faring layer or board sand all over.

- Align and pre-drill rudder stock port.

- Apply epoxy primer coating.

- Cut brad nail attachment of hull to mold.

- Lift hull and flip over. Remove mold assembly and install upright supports. Install hull on base and supports. Following these steps the external surface will be left unpainted and the hull flipped over to begin internal structure work.

.JPG)

.JPG)

.JPG)