All forms are now cut and aligned. A recheck of profile points are within 3mm.

Stations 8, 7, 6 and the transom points do not create a fare line. Does anyone know if this is normal for F15 hulls? I discovered the comment section is not working and so a message to wymanrt@yahoo.com would be great. I imagine I will redo this section with a batten and miss the loft points by several mm. The form is almost ready for lamination work.

The first marking of center-line points measured from the baseline shows they are skewed. Will have to reset sections of form and remark or rotate baseline reference.

Stations 8, 7, 6 and the transom points do not create a fare line. Does anyone know if this is normal for F15 hulls? I discovered the comment section is not working and so a message to wymanrt@yahoo.com would be great. I imagine I will redo this section with a batten and miss the loft points by several mm. The form is almost ready for lamination work.

The first marking of center-line points measured from the baseline shows they are skewed. Will have to reset sections of form and remark or rotate baseline reference.

Moving along I decided to construct the backbone stand alone in the upright or flat orientation (TBD) then build the stations and insert it within them. The cross members will be added after the initial lamination and shaping and finally trimmed within the shell fairing. Building base is coming along. The backbone went through several revisions to where finally the cross pieces (frames and buttresses) are moved to the top of the lamination stack instead of in the middle making the work easier. A 10 mm cap will sandwich both assemblies. A few more days of vacation should get the lamination started.

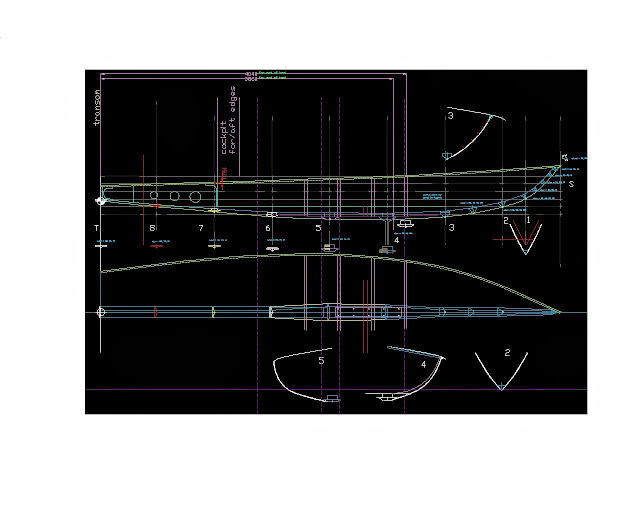

Backbone construction: Planning to work with African Mahogany for majority of backbone along with Oak for frames and ? for buttresses at four points in the area of the keel flange. Two frames will be fore and aft of keel centroid longitudinally and one set will terminate near the shroud attachments. The basic layout still being refined is shown below. Stiffness of stern area up to rudder attachment is being studied with shell and panels. Load distribution out from keel attachment along with other stress points; mast, shrouds, jib, etc. will tweak the design before any molds can be setup.

Finished parts waiting for a home. Still work to do here but at a good stopping point until the hull forms.